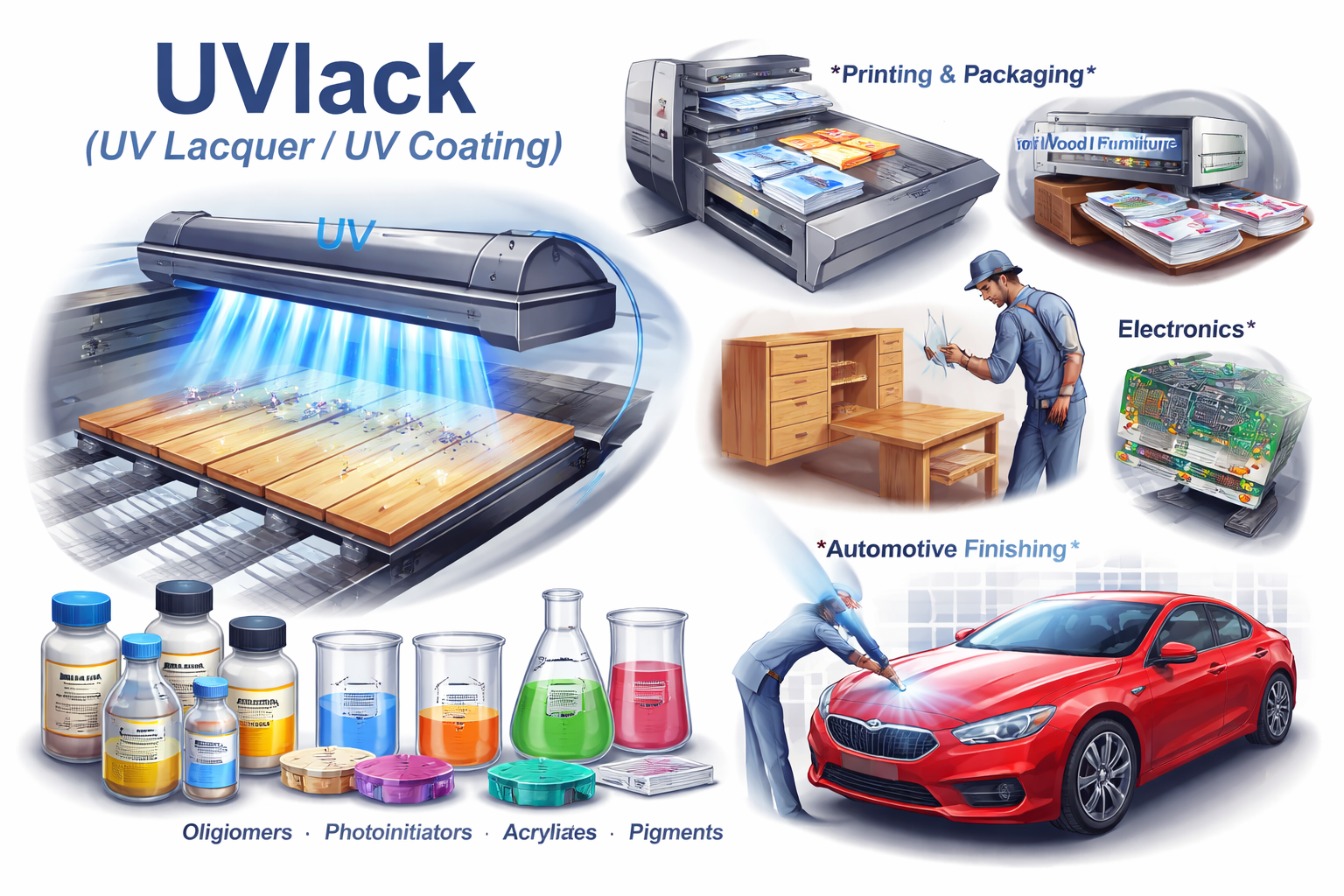

In modern industrial finishing and surface treatment, few technologies have grown as rapidly and as widely as UVlack — short for Ultraviolet (UV) cured lacquer or coating. UVlacquer is part of a broader category of UV‑curable materials that set quickly when exposed to ultraviolet light. This process offers remarkable advantages in speed, performance, sustainability, and cost‑effectiveness compared to conventional solvent‑based coatings.

This article explores everything about UVlack — from its chemical basis, manufacturing process, and applications to benefits, environmental impact, limitations, and future developments. Whether you are a student, engineer, manufacturer, or curious reader, this guide will illuminate why UVlacquer has become a cornerstone technology in printing, woodworking, electronics, automotive finishing, and more.

1. What Is UVlack?

UVlack (or UV lacquer) is a surface coating that cures (hardens) through exposure to ultraviolet (UV) light rather than by evaporation of solvents or thermal drying. UVlacquer typically consists of:

- Oligomers and Monomers — The resin base that forms the hard coating.

- Photoinitiators — Chemicals that absorb UV light and trigger polymerization.

- Additives — For adhesion, flexibility, scratch resistance, color, and other properties.

- Pigments or Dyes — Optional, for colored or decorative finishes.

When applied to a substrate (like paper, wood, plastic, metal), and then exposed to a UV light source, the photoinitiators activate rapidly, causing the oligomers and monomers to crosslink into a hardened, durable polymer network — all in a fraction of a second to seconds.

2. The Science Behind UV Curing

At the heart of UVlack’s technology is photopolymerization:

- Photoinitiation — UV light (typically in the 200–400 nm range) strikes the coating.

- Free‑Radical or Cationic Activation — Photoinitiators break down into reactive species.

- Chain Growth — Oligomers and monomers form long polymer chains.

- Crosslinking — These chains link together into a rigid, highly cohesive network.

Because this reaction does not rely on heat or solvent evaporation, UV‑cured coatings can reach full strength almost instantly, retain volatile organic compounds (VOCs) at near zero, and produce minimal emissions.

3. How UVlack Is Applied

The application methods depend on the industry and substrate:

3.1 Printing and Paper Finishes

- UV Coating on Printed Sheets: UVlacquer is often applied over offset, digital, or flexographic prints to protect them and enhance gloss or matte effects.

- Spot UV: A variation where only specific areas (such as logos or images) receive the UVlacquer for a contrasting, tactile effect.

3.2 Wood and Furniture

- UV Lacquer Sprays or Rolls: Used on hardwood floors, cabinetry, and furniture for a robust, scratch‑resistant surface.

- UV Roller Coating: Industrial lines use rollers to apply even coatings on panels or boards before UV curing.

3.3 Plastics and Electronics

- Protective Coatings: To safeguard plastics, circuit boards, and electronic components against moisture or handling abrasion.

- Optical Clarity Coatings: For lenses and displays requiring high transparency.

3.4 Automotive and Industrial Finishes

- Clear Coats and Specialty Layers: Applied over base colors for depth, durability, and UV/weather protection.

- Functional Coatings: Anti‑scratch, anti‑yellowing, or heat‑resistant variants.

4. Benefits of Using UVlack

UVlacquer offers numerous advantages over traditional coatings:

4.1 Speed and Productivity

Traditional solvent‑based finishes may take hours to dry and require controlled environments. UVlack cures in seconds under UV lamps, enabling much higher throughput and shorter production cycles.

4.2 Environmental and Health Benefits

- Low VOCs: Because UVlacquer does not rely on solvent evaporation, VOC emissions are drastically reduced.

- Reduced Hazardous Waste: Less solvent handling and disposal are required, making production cleaner and safer.

4.3 Durability and Performance

- Superior Hardness: UVlakcs often yield harder surfaces than conventional coatings.

- Chemical Resistance: They resist many chemicals, solvents, and wear.

- Enhanced Gloss and Clarity: Particularly valuable in graphics and decorative surfaces.

4.4 Energy Efficiency

UV curing requires less energy than heat‑cure systems because it uses focused light rather than prolonged heating of large surfaces or ovens.

4.5 Design and Functional Flexibility

UVlacquer can produce distinct surface effects — high gloss, satin, matte, textured, or embossed looks — without extra drying time.

5. Environmental Impact and Sustainability

In an era of heightened environmental awareness, UVlack fits well with sustainable manufacturing goals:

- Minimal Air Pollution: Near‑zero VOC emissions contribute to cleaner air quality.

- Energy Conservation: Shorter curing times and lower power consumption reduce carbon footprint.

- Safe Working Conditions: Fewer flammable solvents and less indoor air contamination improve worker safety.

However, there are environmental considerations too:

- Production of Raw Chemicals: Oligomers, photoinitiators, and additives require careful environmental assessment.

- End‑of‑Life Recycling: UV‑cured plastics and wood panels can be harder to recycle due to permanent crosslinking.

Modern research, therefore, focuses on biobased UVlacquer systems, recyclable coatings, and safer photoinitiators to further reduce impact.

6. Industry Applications in Detail

6.1 Printing and Packaging

One of the oldest and most visible uses of UVlacquer is in commercial printing:

- Covers and Booklets: UVlacquer enhances durability and aesthetics.

- Luxury Packaging: Offers high shine and depth, elevating brand appeal.

- Folding Cartons: UV lacquers protect graphics during transport and shelf life.

- Spot UV Effects: Create contrast and tactile feelings that attract consumers.

The printing industry benefits from vibrant colors, faster press speeds, and robustness unmatched by solvent or water‑based coatings.

6.2 Woodworking and Furniture

Fine woodworking demands finishes that protect and showcase the natural beauty of wood. UVlacquer coatings:

- Resist scratches and stains

- Enhance color and grain definition

- Allow rapid production in factory lines

Furniture manufacturers often integrate automated UV coating systems that spray and cure boards in continuous processes. This capability reduces labor and increases uniformity compared to hand‑applied, traditional varnishes.

6.3 Automotive, Aerospace, and Transport

Surfaces in vehicles and transport equipment must withstand weather, UV light, abrasion, and chemicals. UVlacquer systems contribute to:

- Clear coats over automotive paint

- Protective films on interior parts

- Functional finishes resistant to heat and wear

The ability to engineer customized functional properties (e.g., antistatic, anti‑fog) makes UVlacquer attractive in high‑performance sectors.

6.4 Electronics, Optics, and Specialty Components

In electronics, miniaturization and precision are paramount. UVlacquer coatings provide:

- Conformal protective layers on circuit boards

- Optically clear coatings for displays and lenses

- Barrier coatings for sensors and connectors

These applications exploit UVlacquer’s precision, clarity, and reliability.

7. Types of UVlack and Variants

UVlacquers vary widely depending on chemistry and function. Major categories include:

7.1 Acrylate‑Based UVlacquers

The most common type, offering:

- Fastest cure speeds

- High hardness and gloss

- Good adhesion on many substrates

Primarily used in printing, plastics, and general finishes.

7.2 Epoxy‑Modified UVlacquers

Provide better chemical resistance and adhesion, favored in:

- Electronics

- Industrial coatings

- High‑performance environments

7.3 Flexible or Matte UVlacquers

Engineered for surfaces requiring:

- Flexibility without cracking

- Reduced gloss (matte finish)

- Special tactile characteristics

Used in furniture, packaging with premium feel, and decorative products.

8. Equipment and Curing Systems

Successful UVlacquer application depends on proper equipment:

8.1 UV Light Sources

- Mercury Vapor Lamps: Traditional, broad UV spectrum.

- LED UV Lamps: More energy‑efficient, longer‑lasting, and cooler (less heat damage).

LED UV technology is rapidly replacing older lamps in many industries.

8.2 Application Tools

- Roll coaters

- Spray booths

- Flood bars

- Screen coaters (in printing)

Automation and precision dosing systems ensure consistent coverage and minimal waste.

9. Safety and Handling

UVlacquer raw materials have specific handling requirements:

- Photoinitiators and monomers can be irritants or sensitizers.

- Proper ventilation and PPE (gloves, goggles) are important.

- Curing units emit UV light, so shielding and interlocks prevent exposure.

Training and safety protocols ensure worker health and regulatory compliance.

10. Challenges and Limitations

Despite its advantages, UVlacquer has challenges:

10.1 Substrate Compatibility

Some materials (like heavily pigmented or thick absorptive surfaces) may not cure well without special formulations.

10.2 Initial Equipment Cost

UV curing systems and LED lamps require a higher upfront investment than conventional ovens or drying lines — though they pay back via speed and efficiency.

10.3 Recycling and End‑of‑Life

UV‑cured polymers are highly crosslinked, making them harder to melt down or dissolve for recycling. Innovators are developing removable or degradable UV coatings to improve circularity.

11. Market Growth and Trends

The UVlacquer market continues to grow due to:

- Demand for faster production

- Stricter environmental regulations

- Growth in packaging and digital printing

- Adoption of LED UV systems

- Rising quality expectations in automotive and electronics

Emerging trends include:

- Biobased UVlacquers from renewable raw materials.

- Smart coatings with sensing, self‑healing, or antimicrobial features.

- Inkjet UVlacquers for digital finishing.

- Hybrid systems combining UV with other curing technologies.

12. Comparing UVlack to Other Coating Technologies

| Feature | UVlack | Solvent‑Based | Water‑Based | Powder Coating |

|---|---|---|---|---|

| Drying/Curing Time | Seconds | Hours | Hours | Minutes |

| VOC Emissions | Very Low | High | Moderate | Very Low |

| Energy Use | Low | Moderate | Moderate | Moderate |

| Surface Hardness | High | Variable | Moderate | High |

| Gloss Options | Excellent | Good | Good | Moderate |

| Substrate Flexibility | Good | Good | Good | Limited |

UVlacquer often outperforms traditional coatings in speed, durability, and environmental impact — especially where high throughput and high quality are essential.

13. Case Studies and Real‑World Examples

13.1 Commercial Printing

A printing house replacing conventional aqueous coatings with UVlacquer increased press speed by 35%, reduced drying floor space by 50%, and improved image durability, leading to fewer customer complaints and returns.

13.2 Furniture Production

A furniture manufacturer transitioned to UVlacquer finishing on wood panels, enabling same‑day shipping instead of multi‑day drying cycles — significantly shortening lead times and increasing customer satisfaction.

14. The Future of UVlacquer

Innovation in UVlacquer continues to accelerate. Anticipated developments include:

- Higher performance LED UV systems

- Eco‑certified, low‑toxicity chemistries

- Coatings with embedded functionality (antimicrobial, self‑cleaning)

- Integration with digital printing and automated manufacturing

As manufacturing evolves toward faster, greener, and smarter processes, UVlack is poised to play a central role.

15. Conclusion

UVlack (UV lacquer/UV coating) represents a transformative coating technology that combines speed, durability, aesthetic richness, and environmental responsibility. From printing and packaging to furniture, automotive, and electronics, it enables manufacturers to achieve finishes once thought impossible with traditional methods.

Although challenges remain — such as recycling and upfront equipment cost — continuous innovation is expanding UVlacquer’s potential. With environmental pressures rising and production cycles accelerating, UVlacquer is not just a niche technology — it’s becoming an industrial standard.